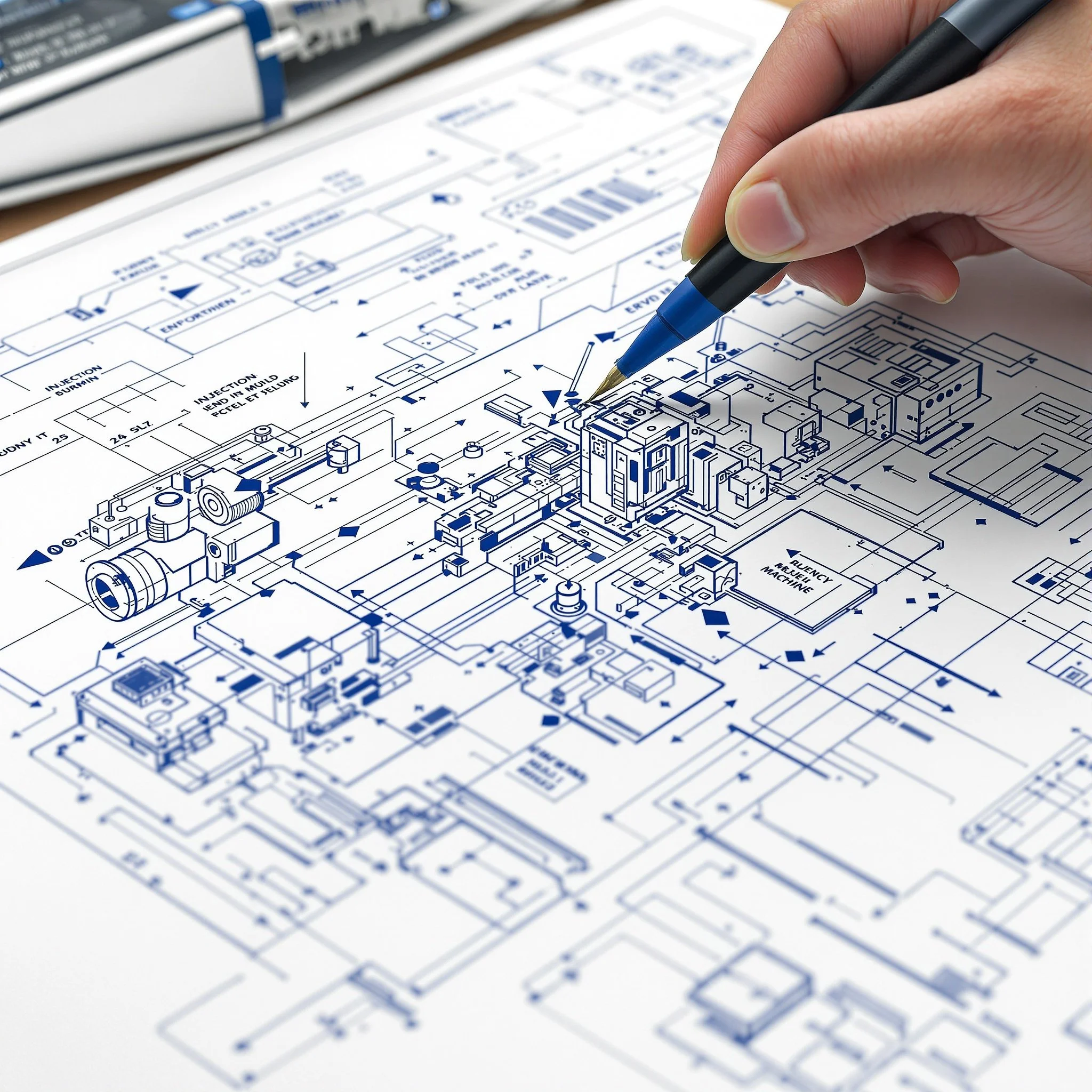

Stop troubleshooting and get moulding.

Solve the science behind your engineering plastic injection moulding problems with end-to-end technical engineers + suppliers

Eastern Plastics Machinery™

Our Clients

The Secret is in the

Science

Stuck troubleshooting and not hitting production KPIs?

Engineering plastic is complex and costly to get wrong. But sometimes your technical team get stuck in troubleshooting returning low production KPI’s, costly rejects and a lack of capability for competitive edge in product design.

Have you ever considered its not your complex product design or material keeping you in troubleshooting, but the science behind your equipments build thats shrinking your operating window?

Eastern Plastics Machinery™ founders-come-technical engineers spent 50+ years shadowing the mastermind creators of Japanese plastic injection moulding machine technology to help pharmaceuticals, household, IT, component, motor, electrical and construction clients solve technical problems, increase operating windows, supply, fit and support the widest range of highly bespoke equipment.

We aim to help clients:

Solve the most unique plastic moulding technical issues with the right equipment (with highly bespoke add ons)

Vastly drop temperatures and widen operating windows to dramatically increase production and design capability

Reduce production downtime needed for cleaning and breakdowns

Build full production cell’s from scratch to get into production fast

Ensure technology is Plug-and-Play and easy to use with very little training or need for additional controllers

Solve complex moulding using hands-on technical suppliers

Our team aren’t just suppliers, we’re hands-on engineers too.

Using 50+ years hand’s on experience we’ve helped solve a huge range of problems across pharmaceuticals, component, connectors (including mobile, under bonnet and solar), water and air fittings, motor, electrical & construction.

Full guidance towards the right equipment

to remain competitive

Get full guidance on the latest technology thats right for you, plus ensure your production/design capability remains competitive.

End-to-end build & support from full cell through to spares

Our teams provides a holistic service from complete cell build, testing, technical mould problem solving, project management, material, support from Japanese and Eastern’s engineers and spares.

Highly bespoke

plug-and-play equipment.

Largest range worldwide

Our partners provide the widest selection in the market of Japanese equipment from all electric machines to end-to-end ancillary, all with fully bespoke customisation to fit you and your current setup.

Our Products.

Our Products.

40°C lower temperature

Zero degradation + rejects

80% reduction in tool cleaning

Double productivity

Faster return on investment

Your operating window will make or break your production, design capabilities, part cost and ultimately returning your investment.

We only supply Japanese plastic injection moulding equipment designed to double your productivity and widen design capabilities, with the largest range of bespoke equipment that slots into current operations with very little training or additional controllers.

We supply all electric JSW Moulding Machines, Matsui Ancillary and Dryers, Nihon Yuki Screws and Feeders, Sailor Robotics and Seiki Hot Runners all with uniquely patented technology, with some delivered direct from Europe in weeks not months.

-

Our proud partner Japanese Steel Works (JSW) have the widest range of highly bespoke low and high tonnage all electric injection moulding machines for sale in the UK of any other provider in the market.

Including Vertical Clamp Rotary Table, Magnesium and clamping force of up to 3,000 tonnes - with some available for delivery direct from Europe in as little as 2 weeks.

Click here or the button opposite for full product details -

Prone to degradation, engineering plastics can be challenging to mould.

Our partners at Seiki realised standard hot runners built with 1 body temperature control ended up being the cause of degradation and productivity loss.

They created a uniquely patented tip heater valve and probe hot runner design with a simple to operate gate temperature control to solve this problem.Click here or the button opposite to see how Seiki hot runners work

-

Engineering plastic is hydroscopic and absorbs moisture from the environment, failure to remove this moisture or the fines and dust prior to injection moulding causes common problems such as silver streaks, black specks and rejects that can ruin your production KPI’s.

Our partners Matsui recognised standard drying systems were actually the cause of these common problems.

Matsui cut drying time by half, keep production output constant and eradicate silver streaks and black specks, with their worlds first continuously cycling honeycomb desiccant rotor and hopper filtration system.

Click here or the button opposite to see how Matsui dryers work -

At ejection and assembly, teams can loose a frustrating amount of hours due to lack of product consistency and have no choice but to waste expensive material due to multi-part variation, or, at ejection - deal with repetitive breakdowns and tool breakages causing teams to slow robot movements (reducing productivity and your bottom-line).

Born originally from the small and intricate pen production and assembly in 1970, Sailor Robotics recognised the need for robots that give their assembly teams fast and highly consistent products that dramatically reduce faults at assembly.

They created a wide range of lightweight robots with rack and pinion technology and unique ‘harmonic curves’ in the robots movements, able to deal with sudden changes in movement without vibration, reducing breakdowns to years not months, halving takeout time and keeping part consistency.

Click here or the button opposite to see how Sailor Robots work

Trusted Supplier of

Supplying 50+ years of holistic technical, and unstoppable productivity.

Three generations of passion.

Started by technical engineers - the late Ken Siddall in 1976, joined by his son Chris Siddall in 1978, and later joined by Chris’ daughter Michelle Siddall in 2025 - Eastern Plastics has been the leading UK supplier and technical support for Japanese Steel Works, Seiki, Matsui and Sailor Robots for clients all over Europe for over 50 years.

Flying to and from Japan for a decade throughout the 1970’s, Chris Siddall moved from his trade in jewellery and diamond mounting and trained as a expert engineer in Japan alongside mastermind of research and development at Meiki (part of Japanese Steel Works) Hideo Horiguchi at their laboratory and test centre in Kwagucci, Tokyo.

He developed a deep understanding how to building machinery cell’s from the ground up, developing patents, researching molecular materials and understanding the scientific reasons behind ‘why’ machinery throughout the injection moulding machine network react they way they do.

Holistic unstoppable productivity for plastics injection moulding manufacturers became Chris and Ken Siddall’s lifetime passion, and has helped solve some of the most complex injection moulding technical problems for some of the biggest clients across the fields of electrical, automotive, healthcare, medical and waterworks including Johnson & Johnson, John Guest and Molex.

Meet The Team

Contact Us

Interested in our products or would like to talk through a technical problem of your own?

Feel free to contact us via the below or complete our the form

Telephone: +44 1376 56 22 88

Email: info [AT] easternplastics.co.uk